Current Position:Home > Lean

Current Position:Home > Lean

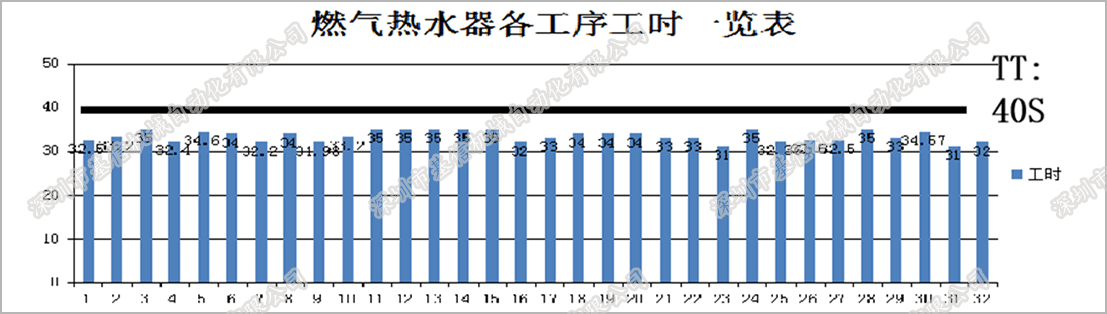

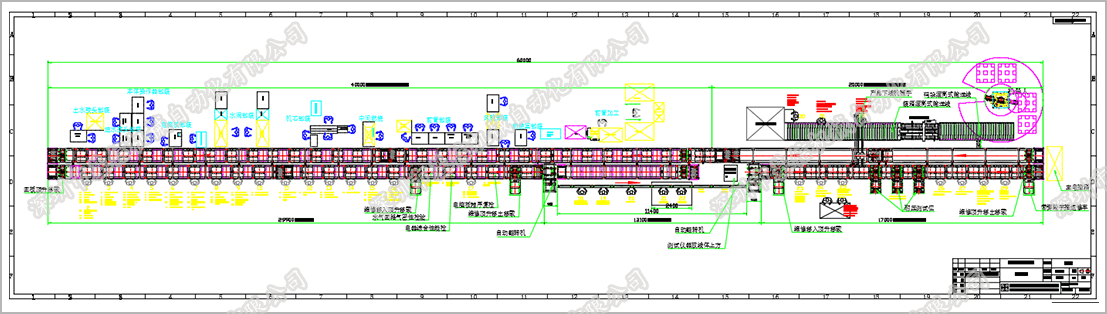

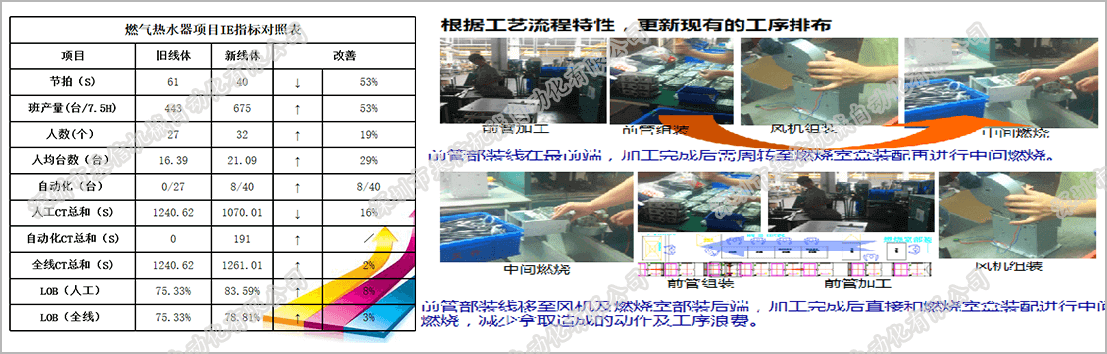

Field research, data analysis, overall calculation, combined with existing technology, reorganization of processes, value stream analysis, elimination of island operations, and improvement of LOB; use lean thinking to design the production line, and each functional module is reasonably designed and compatible with a variety of models Line production to enhance the high flexibility of the production line.

The basic goals of lean production: zero inventory, high flexibility, and defect-free; the partial assembly line is integrated with the final assembly line, WIP is directly placed on the line material frame, reducing the temporary storage and turnover of WIP, and the effect of material foolproof and real-time monitoring. Through motion analysis, Mode method and other IE methods, standardization of working hours and work, a reasonable production line layout is designed according to capacity planning.