Intelligent

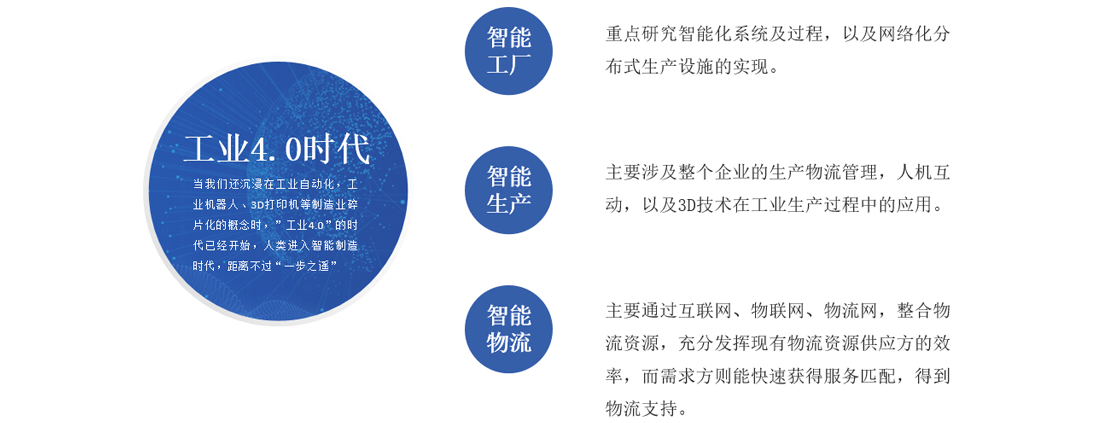

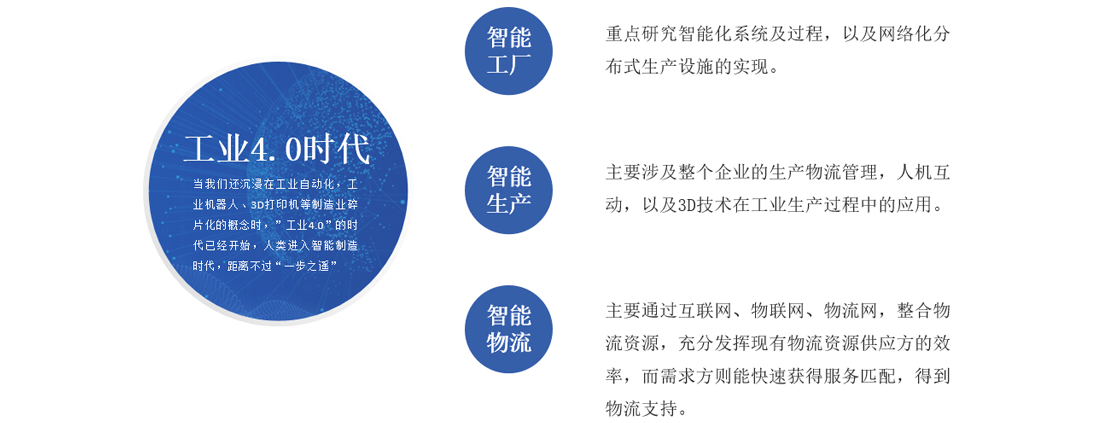

When we are still immersed in the concept of industrial automation, industrial robots, 3D printers and other manufacturing fragmentation, the era of "Industry 4.0" has begun, and human beings are only "one step away" into the era of intelligent manufacturing.

The three main themes of Industry 4.0: smart factories, smart production, and smart logistics.

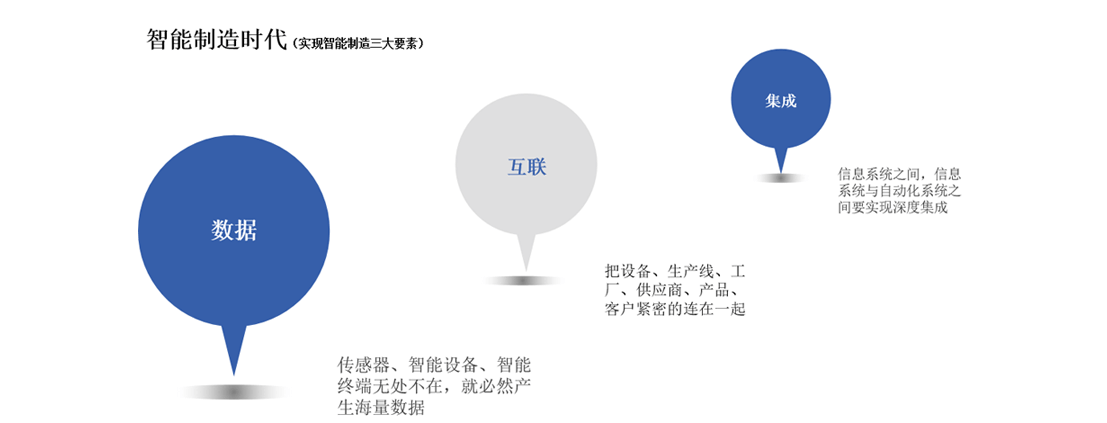

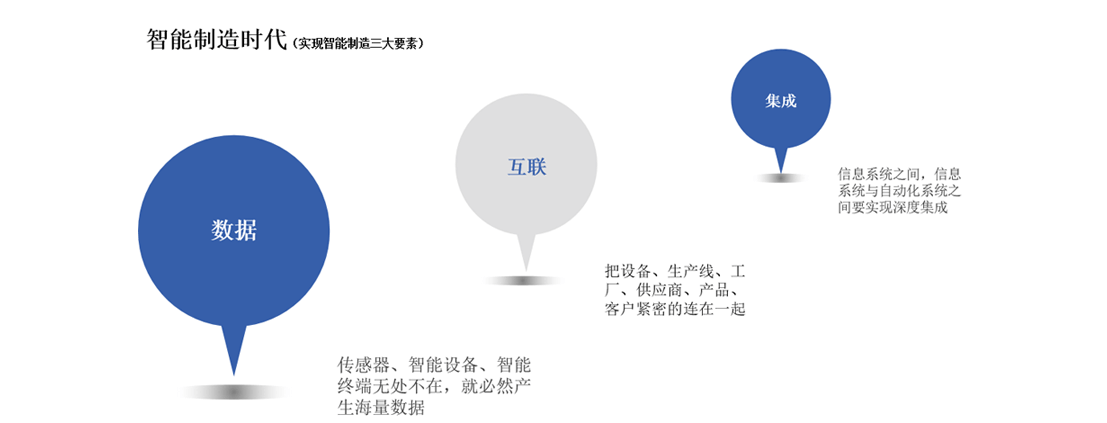

Three elements to realize intelligent manufacturing: data, interconnection, and integration.

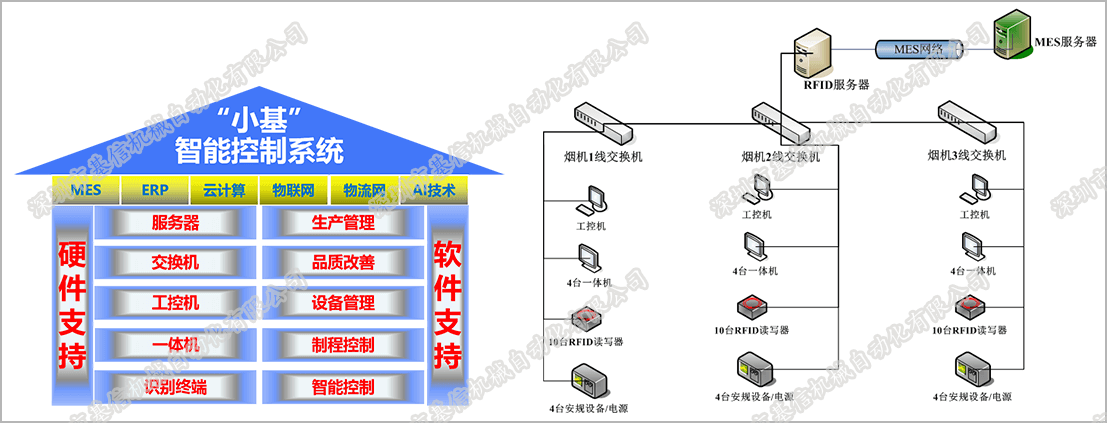

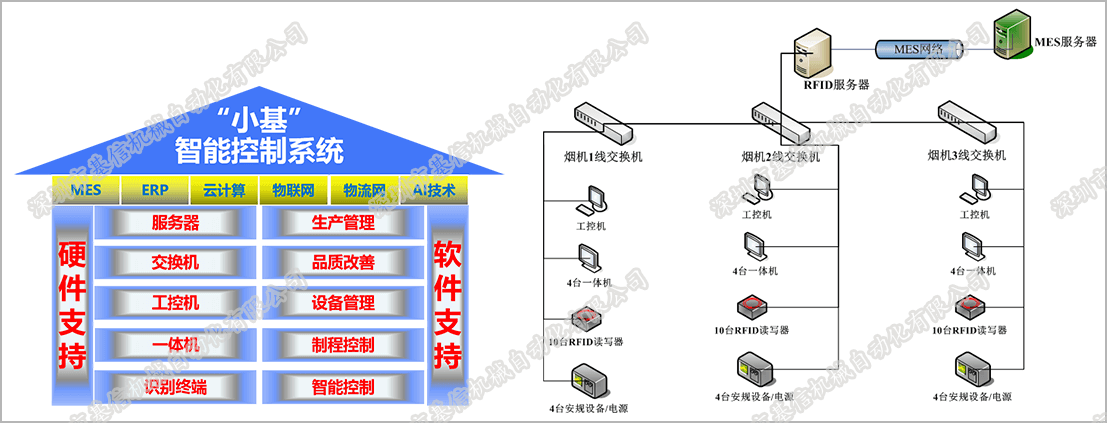

"Xiaoji" intelligent control system, network topology diagram.

The intelligent control system is divided into production management, equipment management, quality traceability, and intelligent control.

Production management: personnel management, production work order, shutdown key binding;

Equipment management: equipment monitoring module (data acquisition system), equipment management module (authority management, overall efficiency (OEE), operation log recording), equipment operation and maintenance module (preventive maintenance, abnormal parameter alarm, equipment failure management);

Quality traceability: real-time upload and storage of inspection data, key components, personnel information, maintenance records and other data;

Intelligent control: In-depth integration of production lines, robots, and vision systems, real-time switching of models, zero waiting.

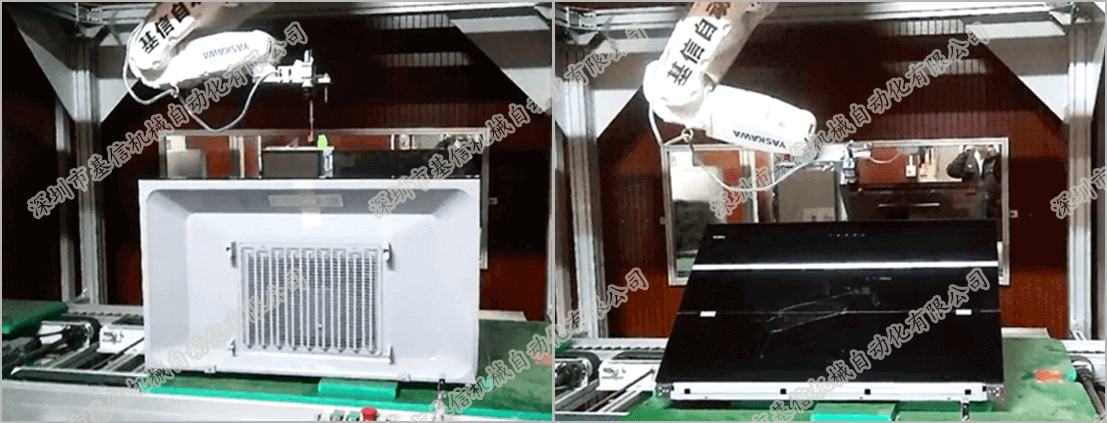

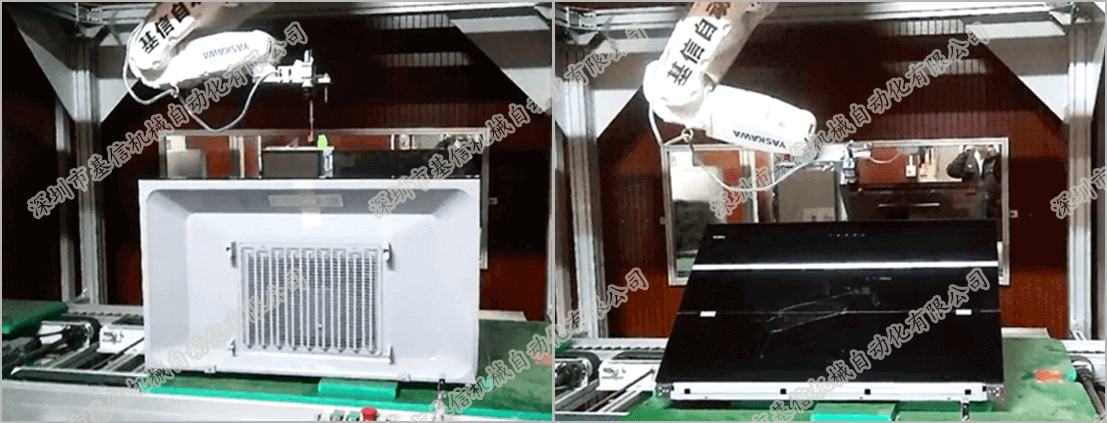

The application of intelligent in the kitchen appliance industry, the deep integration of intelligent equipment-informatization and automation, the automatic docking of safety, performance, air volume, lighting, Bluetooth, WiFi and other testing items, automatic keystrokes, and complete "unmanned" testing. The test data is uploaded to the MES and local database in real time. The intelligent control system supports the real-time switch model of the station, carries out zero-waiting model change, without manual intervention, and improves the corporate image.

Current Position:Home > Intelligent

Current Position:Home > Intelligent