Current Position:Home > Informatization

Current Position:Home > Informatization

Informatization is divided into digitization, data collection, process control, information interaction, and product traceability.

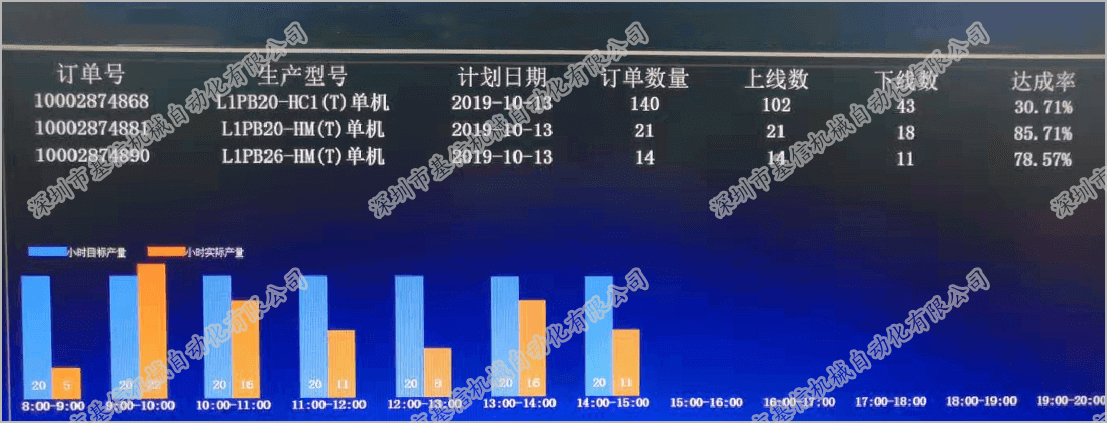

Digitalization is divided into safety management, production line management (number of production plans, models, quantities, and actual production conditions), process kanban, and Andon system.

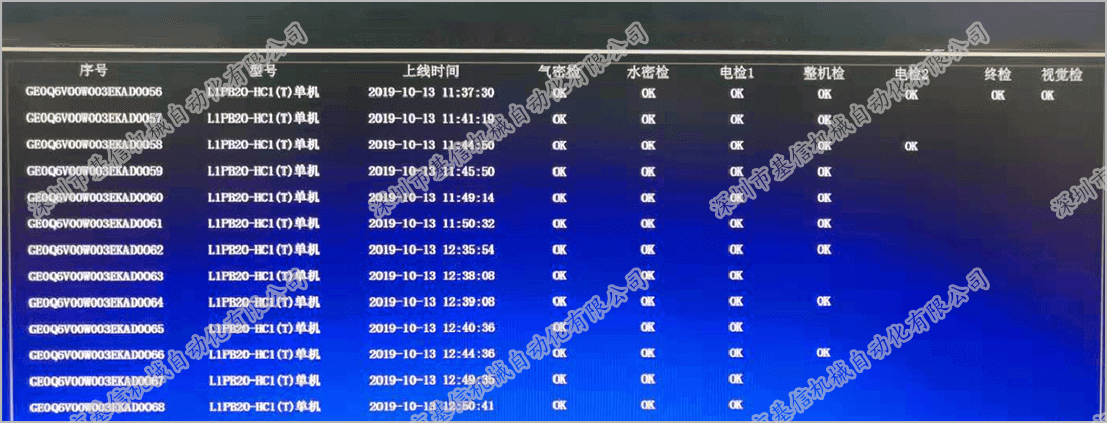

The data is divided into human, machine, material, method, environment, monitoring production line faults, monitoring production line beats, counting production line shutdowns, collecting information on key positions, collecting product inspection data, and repairing data.

Process control is divided into real-time adjustment of production line beats, equipment maintenance timeliness, detection results and the binding quantity of key parts, self-determination whether to go offline, printing host name tags, accessory scan codes, finding quality abnormalities, and real-time processing.

Information interaction is divided into work order information issuance---work order number, schedule number, product number, production quantity, process path (product flow node), product information issuance--work order BOM, including key part information and attachments Information, MES-RFID-robot-detection instrument-vision-line body, etc.

Product traceability is divided into whole-process data package management such as product information, personnel information, equipment information, and key information.